This side takes load... Pull to spill...

Make fast to tender Lead near to hand

|

| Tumble HitchFrom www.animatedknots.com The wooden dowel represents the anchor's shank |

Seek the wisdom that will untie your knot.

-- Rumi

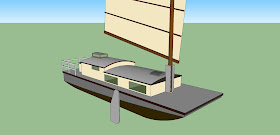

Tumble Hitch: A Useful Knot for Rowing Out an Anchor

Rowing out an anchor in a gale or more of wind is serious business.

After considerable experimentation, the method we settled on is as follows:

- One of us takes position at the bow, one in the tender.

- The anchor and chain are transferred to the tender.

- Line is paid out from the boat as the tender works to position.

- The line is made fast at the boat (by signal or pre-arrangement).

- Chain is paid out from the dory by hard rowing against the fixed line.

- At the perfect moment, the anchor is thrown from the tender.

- Anchor is set from the boat.

Sounds simple, right?

Well... we find that sitting toward the tender's bow depresses it to lower windage, while the stern lifts high and acts as a riding sail for easier rowing into the wind (avoids blowing off, beam on).

Tossing the anchor and last bit of chain over, clear of oars, locks, one's own feet and the gunnel is no mean feat. It can hang up in a number of ways that all fail more or less dangerously.

Enter the Tumble Hitch - a variant of the Highwayman's Hitch.

The latter was said to have been used by thieves who tied their horses with this easy-to-tie, quick-release hitch for a fast get-away. Only problem is that it's not very stable and can capsize and release prematurely. The Tumble Hitch was devised in 2004 by Dan Lehman as a more stable solution.

What's unusual about both hitches is that, where others take one or more round turns around whatever they're hitched to, these open like a hand releasing. For anchoring purposes, that means a clean, anti-fouling release without unraveling any round turns.

The Tumble Hitch doesn't slip quite as readily as the Highwayman's... consider a smoother finished, braided line similar to the one shown. Laid and 'textured' lines have enough friction to require one or more harder pulls to release.

So here's the drill...

Well... we find that sitting toward the tender's bow depresses it to lower windage, while the stern lifts high and acts as a riding sail for easier rowing into the wind (avoids blowing off, beam on).

Tossing the anchor and last bit of chain over, clear of oars, locks, one's own feet and the gunnel is no mean feat. It can hang up in a number of ways that all fail more or less dangerously.

Enter the Tumble Hitch - a variant of the Highwayman's Hitch.

The latter was said to have been used by thieves who tied their horses with this easy-to-tie, quick-release hitch for a fast get-away. Only problem is that it's not very stable and can capsize and release prematurely. The Tumble Hitch was devised in 2004 by Dan Lehman as a more stable solution.

What's unusual about both hitches is that, where others take one or more round turns around whatever they're hitched to, these open like a hand releasing. For anchoring purposes, that means a clean, anti-fouling release without unraveling any round turns.

The Tumble Hitch doesn't slip quite as readily as the Highwayman's... consider a smoother finished, braided line similar to the one shown. Laid and 'textured' lines have enough friction to require one or more harder pulls to release.

So here's the drill...

- Make fast to the tender, slightly aft of center, with the line end that holds strain.

- Tie the hitch around the anchor just behind the flukes, let hang a foot or two below the tender's bottom.

- Lead the spill end up and slack to a point handy to the oars(wo)man

- Row on out to position.

- Pull the slip end to release.

We haven't tried this yet, in any harsh weather. But initial tryouts are promising.

Definitely feels safer!

Definitely feels safer!

*****

Here are some animated tutorials for the Tumble Hitch:

http://www.animatedknots.com/tumble/index.php

https://www.netknots.com/rope_knots/tumble-hitch